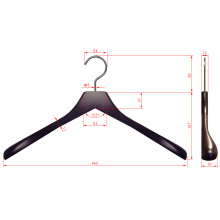

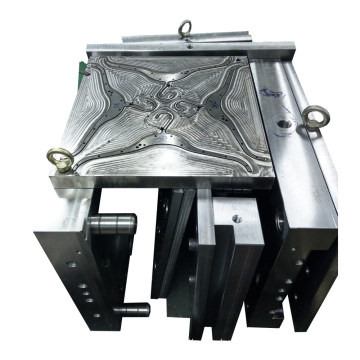

Hot Selling Plastic Hanger Mold

Hot Selling Plastic Hanger Mold

| Packaging: | For Parts: bulk or individual pack, upon customer's demands with exported carton box. For Mold: Standard exported wooden box packed, fumigation process (upon required). |

|---|---|

| Productivity: | 1000000 |

| Brand: | intertech |

| Place of Origin: | taiwan |

| Supply Ability: | 1 Set/Sets per Month |

Click on the follow link to find out more information: https://www.taiwanmouldmaker.com/household-products-mold/

Company Info

- Company Name: Intertech Machinery Inc.

- Representative: Intertech Machinery Inc.

- Product/Service: Plastic Mold , Silicone Mold , Rubber Mold , LSR Mold , Plastic Injection Molding , Plastic Molding

- Capital (Million US $): USD110000

- Year Established: 2002

- Total Annual Sales Volume (Million US $): US$1 Million - US$2.5 Million

- Export Percentage: 81% - 90%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 5

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 1,000-3,000 square meters

- Factory Location: No. 20, Lane 417, Min-An Rd., Hsin-Chung City, 24258, Taipei County, Taiwan

- Contact Person: Ms. Debby

- Tel: +886-02-28334646

Premium Related Products

Hot Products

Top grade man clothes hangersChildren's colorful clothes hangersBest selling electroplated women clothes hangerselectroplate hanger for menoblate hook plastic anti-skidding hanger for manChild clothes hanger Kid clothes hangerChildren yellow trousers hangerChildren Trousers HangerTrousers hanger with clipChild colorful trousers hangerDouble lines PVC coated cloth hanger with grooveChild colorful cloth hangerAnti Skidding Rubber Foam HangerDouble lines PVC coated cloth hangerPVC coated trousers hangerMetal Hanger for Tie